Company

We are an international partner to the automotive industry and an innovative lightweight specialist for high-strength spring components and related products. As an owner operated family company, our name is synonymous with long-term, sustainable commercial success.

The Mubea Way

Taken individually, the following points would not constitute a corporate philosophy – but together they give us a picture of what we call “The Mubea Way.” This approach is the result of 100 years of corporate history and also forms the foundation of our company.

Mubea Products

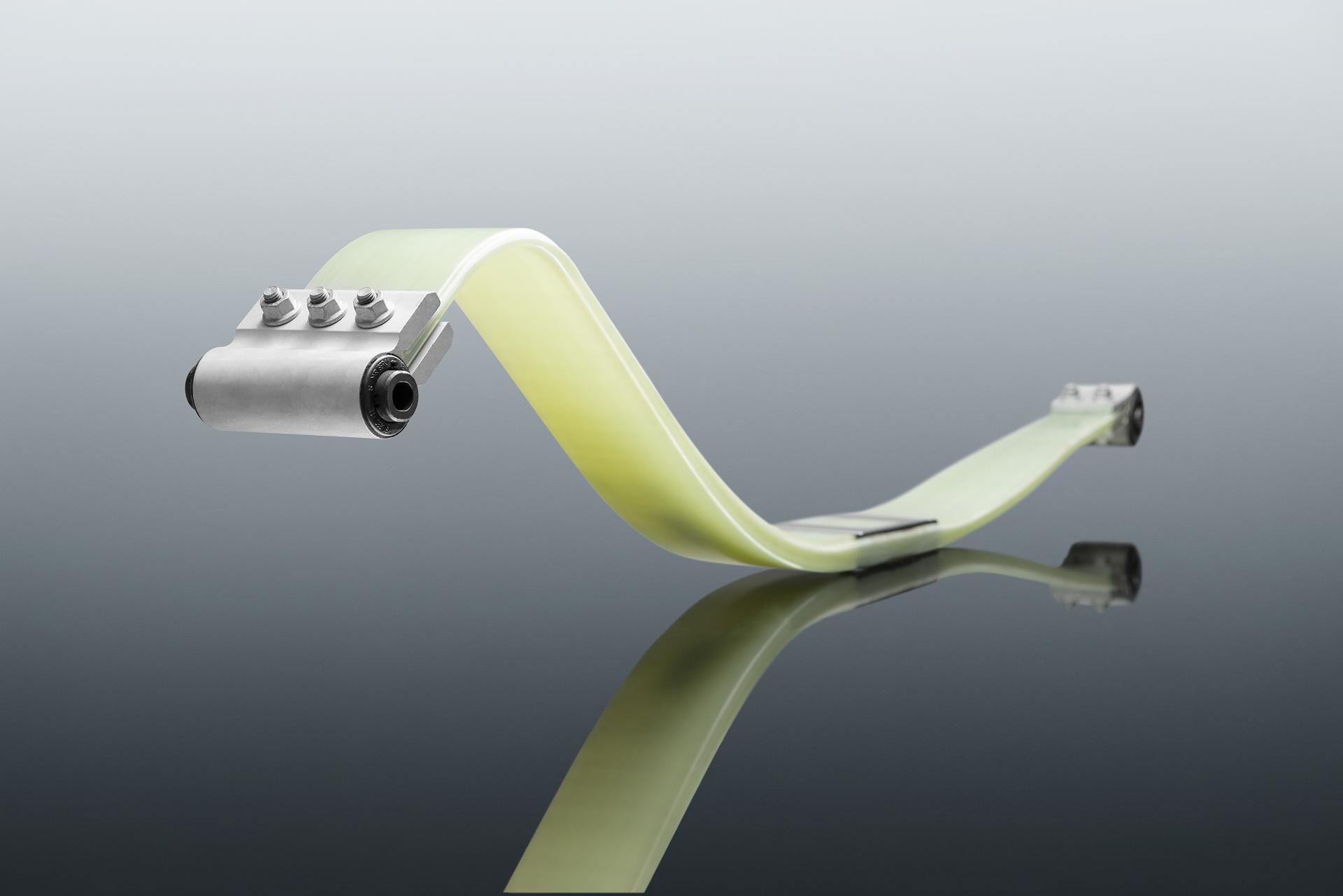

With our unique products and technologies, we have become established as a world market leader. We develop individual solutions with the aim of maximizing weight reductions and offering the greatest benefits to the customer.

MUBEA Career

Our employees are our most important resource. The know-how that they possess is our greatest asset. Their team spirit and dedication are valuable parts of our identity. Join now!