1. Introduction

Solid waste generation is strongly affected by human activities. As population growth increases rapidly, waste generation also increases in the same way. In the European Union, nearly 1.323 kg of municipal waste is generated per person per day [

1]. Due to the insufficient efficiency of waste separation, reuse, and recycling [

2], only 29% of the waste is recycled and the remainder is disposed directly in landfills [

1]. One of the major environmental concerns associated with waste disposal is the large amount of generated landfill leachates (LL) due to the rainwater filtration through waste. LL can be considered wastewater with a complex composition and many toxic and persistent compounds [

3]. Their composition depends on many factors, such as the landfill age, climatic conditions, rainfall intensity, and the presence of toxic/biorefractory wastes in the landfill [

4,

5,

6,

7]. Because of the high variability of the flow and type of pollutants in LL, the traditional activated sludge reactors used in typical wastewater treatment plants are not efficient enough [

4] for it. The worldwide wastewater discharge regulations and standards have become stricter; hence, there is an urgent need to find an effective LL treatment method. Many researchers are investigating new and effective methods for LL treatment, such as sorption on magnetic particles [

2] and other sorbents [

8], reactive granular filters [

9], the use of metallic iron [

4,

10,

11] and other heterogeneous catalysts [

12,

13], Fenton (classical and solar) [

14,

15,

16,

17], electro-Fenton [

18,

19], and other electrochemical processes [

11,

20,

21,

22,

23,

24], usage of different oxidants and their combination [

25,

26], microwaves [

10], ultrasounds [

27], membrane processes [

28], hydrodynamic cavitation [

29], microalgae [

30], biofiltration [

21,

31], supercritical water oxidation [

32], oscillating biological membrane photoreactors [

33], anaerobic digestion [

27,

34], dynamic membrane bioreactors [

35], bio-electro-Fenton [

36], upflow sludge bed reactors [

37], moving bed biofilm reactors [

38], and the sequencing batch reactor [

39]. Moreover, a few review articles have summarized the LL treatment methods [

40,

41,

42,

43,

44,

45,

46].

Chen et al. [

10] applied, among others, the Fe

0/H

2O

2 process for LL treatment. After a process time of 14 min, only 17.9% chemical oxygen demand (COD) was removed for 0.5g Fe

0 and 20 mL/L H

2O

2 reagent doses. One could expect that if the process was extended, the results would be much higher. Small COD removal could be also related to low Fe

0 dose and a big H

2O

2/COD ratio. Ertugay et al. [

47] applied the Fe

0/H

2O

2 process for LL treatment for small 50/150 mg/L reagent doses in a wide acidic pH range. The COD efficiency at pH 3.0 was only ~20 %, while at pH 2.0, it reached ~75%. Martins et al. [

4], on the contrary, tried high Fe

0 doses of up to 125 g/L in the form of iron shavings as well as a low H

2O

2/COD ratio, and obtained a COD removal of up to 48%. Soubh et al. [

13] used a combination of metallic iron, graphene oxide, and persulfate for LL treatment. The impacts of significant parameters on the removal of COD and NH

3 were evaluated. The removal efficiencies for the fresh leachate were 80.87% and 72.38%, respectively, and the biochemical oxygen demand/chemical oxygen demand (BOD

5/COD) ratio increased from 0.25 to 0.52, respectively.

Advanced oxidation processes (AOP) consist of the efficient production of free radicals (primarily HO

•) that effectively oxidize pollutants contained in the wastewater. In the Fe

0/H

2O

2 process, under acidic conditions and as a result of the dissolution processes, the metallic iron becomes a Fe

2+ ion source. Fe

2+ ions undergo oxidation to Fe

3+ in the presence of H

2O

2, while H

2O

2 undergoes conversion to HO

• and OH

−. Reactions 1–5 allow for divalent iron ion production, while reactions 6–7 describe the creation process chemistry of radicals [

48].

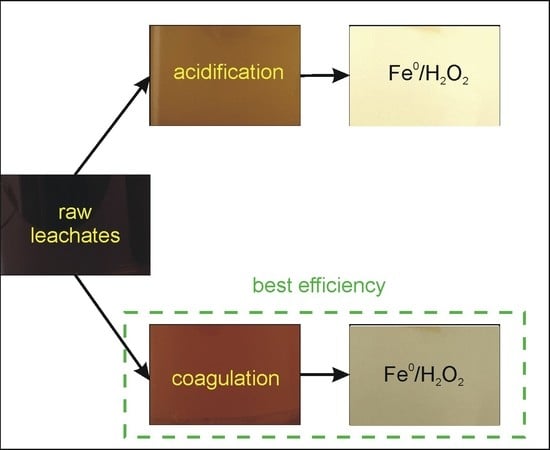

To our knowledge, most Polish landfills do not conduct any leachate treatment. Only several landfills pretreat leachates, usually with pH adjustment and membrane processes. Mostly, the leachates are transported by slurry tankers to municipal wastewater treatment plants. Often, municipal wastewater treatment plants report that the provision of leachate causes problems for their proper functioning. The aim of this study is to assess the possibility of using the Fe0/H2O2 process to decrease the organic pollutant load and increase the LL BOD5/COD ratio. LL were subjected to pretreatment followed by the Fe0/H2O2 process. For the pretreatment process, alternatively, acidification or coagulation at pH 6.0 or 9.0 was used. Then, the Fe0/H2O2 process was applied. For both pretreatment and treatment processes, different reagent doses were tested.

3. Results

3.1. Raw Landfill Leachate Characteristics

The raw LL parameters are presented in

Table 1. Raw LL were characterized by high salinity and content of organic compounds. They had a deep black color and a characteristic smell. The amount of total suspended solids (TSS) was small. TOC and COD values determined in raw and filtered through 0.7 µm glass filter were similar to nonfiltered ones.

3.2. Pretreatment

Three methods were preselected for LL pretreatment: acidification to pH 3.0 and coagulation with FeCl

3at different pH values of 6.0 and 9.0. The obtained results from acidification and coagulation at pH 6.0 and 9.0 are presented in

Table 2. The evolution and the color decrease of LL during the treatment are shown in

Figure 1.

The COD and TOC removal for FeCl

3 coagulation at pH 6.0 and 9.0 is shown at

Figure 2 and

Figure 3, respectively.

The Fe3+ doses applied for coagulation were high, but similar to the ones applied for other types of highly loaded wastewater. In the case of acidification, only a small amount of sludge was produced (c.a. 50 mL/L). We assume that sludge produced in acidification is mostly organic and related to the low dissociation of humic acids in low pH regions. In coagulation, the sludge volume was, as expected, related to the coagulant dose. In the case of coagulation at pH 6.0, for the minimal 500 mg/L coagulant dose, after 30 min of sedimentation, the sludge volume was 200 mL/L, and it increased up to 350 mL/L for the 1500 mg/L dose. In case of pH 9.0, the sludge volume was c.a. 50 mL/L higher for the same coagulant dose. The flocs that formed at pH 6.0 were much bigger than those that formed at pH 9.0.

Pretreatment requires pH adjustment. Acidification to pH 3.0 requires acid usage, while coagulation, as a result of a decrease in pH though coagulant hydrolysis, requires the base to increase pH to 6.0 or 9.0. It has to be taken into account that, of course, salinity is increasing, but when we compare this with the initial salinity, expressed in terms of conductivity (11.08 mS/cm), it is not very important. A much higher degree of salinity is introduced as a result of coagulant usage. Taking into account the FeCl3 structure and molar mass, it could be concluded that 1000 mg Fe3+/L introduces c.a. 2000 mg Cl−/L. Such a chloride content is serious and unsolved in this article.

For both coagulation pHs, a dose of 1000 mg/L Fe3+ could be considered optimal. However, the treatment effect at pH 6.0 was much better in comparison with that at pH 9.0. The TOC and COD removal during the coagulation at pH 6.0 were shown to be dose sensitive, increasing with the dose of coagulant used. A noticeable increase in the effect of treatment was observed until the optimal dose was reached. However, after it was exceeded, a slight deterioration of the effect was observed. Similar observations were shown for the color and turbidity of the sample (data not shown). For the coagulation application at pH 9.0, similar relationships were not observed. Significantly smaller differences in the obtained TOC values as well as in the color and turbidity were observed. In the case of coagulation at pH 9.0, the optimal dose was chosen primarily based on the COD removal and the need for the lowest coagulant usage.

All three pretreatment methods were more effective in BOD5 in comparison with COD or TOC removal. Therefore, as a result of pretreatment, the LL susceptibility to biological treatment decreased, despite the fact that a smaller pollutant load needed to be removed.

The highest but still low efficiency of ammonium compound removal and therefore TKN removal (

Table 2) was obtained by using coagulation at pH 9.0. This is understandable due to the higher volatility of ammonia under alkaline conditions. No significant differences between acidification and coagulation at pH 6.0 were observed in nitrogen compound removal, but coagulation provided a slightly better effect.

3.3. Fe0/H2O2 Process

The results of TOC removal during the Fe

0/H

2O

2 process after acidification at pH 3.0 and coagulation at pH 6.0 are shown at

Figure 4 and

Figure 5, respectively. In both cases, after acidification at pH 3.0 and coagulation at pH 6.0, the Fe

0/H

2O

2 process allowed effective TOC removal.

The efficiency of the Fe0/H2O2 process after acidification increased with the reagent dose. The best efficiency was obtained for an Fe0/H2O2 reagent dose ratio of 8000/9200 mg/L, which removed 294 mg/L to give a final value of 499 mg/L. That achieves a total TOC removal of 53% by the acidification process followed by the Fe0/H2O2 process. The TOC removal over time was almost linear, except for two of the doses—8000/4600 and 4000/9200 mg/L. For them, after 60 min, the treatment effect deteriorated.

Increasing the doses of the reagents during the Fe0/H2O2 process after coagulation at pH 6.0 increases the effectiveness of the process. All in all, increasing the dose of H2O2 to 18,400 mg/L caused deterioration in the treatment effect in comparison with the lower dose. Further increasing the iron dose resulted in the necessity of increasing the agitator power to prevent solid iron sedimentation. These observations were confirmed during the experimental process after coagulation at pH 6.0. In this process, TOC removal was also linear over time. The efficiency of the process also increased with the iron dose. However, in Fe0/H2O2, it can be seen that increasing the Fe0 dose from 4 to 8 g led to only a slight increase in the treatment efficiency, especially for a COD/H2O2 ratio other than 1:4. For all iron doses, a COD/H2O2 ratio of 1:4 provided the best treatment effects. Because of this, 8000/5540 mg/L Fe0/H2O2 reagent doses could be considered optimal, providing a TOC decrease to 268 mg/L after 60 min. That allows a total TOC removal of 75% after the coagulation processes at pH 6.0 followed by the Fe0/H2O2 process. Based on the results, it can be expected that extending the treatment time would increase the efficiency of the treatment process.

As a result of the Fe0/H2O2 process, not only TOC was removed. After coagulation followed by the Fe0/H2O2 process at optimal reagent doses of 8000/5540 mg/L, COD and BOD5 reached 755 and 327 mg/L, respectively. The BOD5/COD ratio—a factor that determines biodegradability—increased to 0.433, allowing LL to be considered biodegradable. Also, humic and other compounds with complex structures, as a result of the radical oxidation process, were oxidized to simpler compounds that could more easily undergo processes of biodegradation.

TNK removal was not effective. After the optimal reagent dose was applied, TKN decreased to 987 mg/L (28.8 % removal). However, leachates, even after the initial treatment, must be subjected to biological treatment.

An attempt was made to increase the efficiency of the Fe

0/H

2O

2 process by supporting it with ultrasound and UV radiation. The results of the enhanced processes are shown at

Figure 6. It was observed that both of the enhancements provided process efficiency deterioration.

3.4. Statistical Analysis

A statistical analysis was done for the Fe

0/H

2O

2 process. The correlation results between the factors (

Table S1) are summarized in

Table 3.

The linear regression results are summarized in

Table 4. Based on the linear regression coefficients, the TOC concentration can be expressed as (4) and (5) for Fe

0/H

2O

2 process after acidification at pH 3.0 and after coagulation at pH 6.0, respectively.

In order to find the importance for each factor on TOC concentration, the optimal scaling test was applied. The importance percentages for each parameter after acidification were 51.5%, 43.8%, and 4.7% for time, iron mass, and the mass ratio, respectively (

Table S2). These percentages also confirm that the mass ratio could be excluded from the model. The time, iron mass and mass ratio importance percentages after coagulation were 62.5%, 22.5%, and 14.9%, respectively (

Table S3). It can be recognized that the importance arrangement is similar to that of the acidification one.

The description and model developed describes this unique sample only. The statistical model allows some important parameters to be predicted, for example, which parameters are important and sensitive for wastewater parameter changes and which are not. What is surprising, in the case of this leachate sample, is that not all parameters that should be important from a chemical or, in another words, “technological” point of view, are important from a statistical point of view.

3.5. Fe0/H2O2 Process Kinetics

Usually Fe

0/H

2O

2 process kinetics is described as first-order or second-order [

49,

50]. This approach was not successful in the case of pretreated landfill leachates. Application of the first- and second-order reaction equations resulted in low correlation coefficients (data not shown). Much better correlation coefficients were obtained using the empirical model (10), as shown in

Table 5 and

Table 6.

The rate of the Fe

0/H

2O

2 process is much more difficult to describe, as metallic iron dissolution, chemical oxidation, coprecipitation and coagulation affect the overall treatment efficiency. Each of these processes is at least partially independent of the others, and they are sometimes contradictory. This sometimes results in a decrease in the effectiveness of the process over time and deterioration of the correlation parameters. This can clearly be seen for high reagent doses in the process after acidification (

Table 5 and

Figure 6).

4. Discussion

4.1. Raw Landfill Leachate Characteristics

The analyzed samples have similar characteristics to others collected from Polish landfills [

17,

49,

51,

52].

4.2. Pretreatment

The acidification efficiency is strongly pH-dependent. Based on the literature review, it was determined that the highest was at pH 2.0 and this decreased with an increasing pH [

49]. As a result of acidification, the dissociation of humic acids is reversed, decreasing their solubility. As a result, they are removed from the leachate in the form of a precipitate [

17].

Acidification to pH 3.0 was chosen as a compromise between the efficiency of the process, the necessity of using a large amount of acid, and the convenience of further treatment processes (no need for pH adjustment). It was observed that during sedimentation, the sediment particles enlarged. The advantage of this pretreatment method is simplicity; there is no need to use expensive reagents and complicated processes. It occurs exactly at this pH which is optimal for the Fe0/H2O2 process. The disadvantage of the process is the sludge formation and considerable time consumption—24 h is required for sedimentation.

The mechanism of FeCl3 coagulation varies depending on the pH of the process. It is assumed that at pH 6.0, the neutralization of colloid charge prevails, while at pH 9.0, an important mechanism is adsorption on the created hydroxide surface.

It could be also concluded that the effect of using acidification is comparable to coagulation at pH 9.0. Comparing all the three pretreatment methods, it could be concluded that coagulation at pH 6.0 was the best method, in terms of organic compounds removal.

The coagulation process is more complicated than acidification; it requires more reagents. On the other hand, the sedimentation time for coagulation is much shorter than in the case of acidification.

Based on pretreatment results, two processes were chosen to be used before the Fe

0/H

2O

2 processes. Coagulation at pH 6.0 was chosen, because of the best treatment effects in terms of organics removal. Also, acidification was chosen, because of its simplicity and the lack of need for further pH adjustment. Coagulation at pH 9.0 was eliminated because of two reasons. The first one was the complication with the pH adjustment: from 7.65 to 9.0, then finally to 3.0. That caused acid/base reagent consumption and an additional salinity increase. The second one was the similar treatment effect to acidification at pH 3.0. The results obtained are in good agreement with the available literature [

9,

39,

52].

4.3. Fe0/H2O2 Process

As a result of hydrogen peroxide decomposition, oxygen bubbles broke up the created flocks, hindering sedimentation. Part of the flocks were disintegrated and permanently suspended in the solution. A similar effect but on a smaller scale was observed in all experiments using large doses of hydrogen peroxide. In the LL, after the process, there was a large excess of unreacted hydrogen peroxide (not determined in the experiment). However, decreasing the dose to reduce the hydrogen peroxide excess resulted in deterioration in the treatment effectiveness.

Due to the high BOD

5/COD ratio, it can be assumed that effective removal of organic and nitrogen compounds will be possible [

34,

37,

38]. Also, other studies suggest that advanced oxidation usage increases biodegradability [

14,

17]. Coagulation with FeCl

3 at pH 6.0, coupled with the Fe

0/H

2O

2 process, proved to have similar efficiency to other processes tested in the available literature, including electrochemical [

11,

20,

36] and advanced oxidation [

15,

16,

17,

19,

21,

25] treatments.

Although it is generally agreed, that a highly saline matrix generates a radical scavenging effect, it also has been proven that the Fe

0/H

2O

2 process is effective for such a matrix. This has been assessed not only for LL, but also for flue gas desulfurization [

48], pharmaceutic [

53] wastewater, and hydraulic fracturing flow back fluid [

54].

For the Fe

0/H

2O

2 process supported with ultrasound and UV radiation, the obtained results contrast with those of Chen et al. [

10], who proved that microwave or heat application enhances the efficiency of the Fe

0/H

2O

2 process. Heating and microwaves accelerate the thermal motion of molecules and, as a consequence, the Fenton reaction rate increases to some extent. When UV and US were applied, an increase in temperature was not observed. The obtained results also contrast with process improvement concepts—UV and US should strengthen the mechanisms of radical generation [

55]. In the case of UV usage, the treatment result increased with the iron dose, but it was weaker without UV radiation. This could be may be associated with the formation of stable complexes that bind iron ions under the influence of light. A similar effect was observed in the case of US application. As it was impossible to magnetically stir the US samples, mechanical stirring with the same stirring speed was applied. Changing the stirring method from magnetic into a mechanic one could result in a decrease in process efficiency because of the paramagnetic properties of oxygen. Under the magnetic stirrer, the magnetic field increased the treatment efficiency [

56,

57]. It was also proved that radical generation is higher in oxic conditions [

50], with a bigger amount of dissolved oxygen [

58], or with more intensive stirring [

53]. The presented reasons for decreasing the efficiency of the conducted process are only hypotheses, not confirmed speculations, and require further confirmation. Based on the obtained results, it could be concluded that process enhancements with UV and US are not recommended, as they do not provide treatment efficiency, and only cause increased complications and costs of the process.

4.4. Statistical Analysis

TOC is strongly correlated to the time and iron mass. The mass ratio–TOC correlation is very weak. Moreover, it is noticeable that the correlation between the independent factors is not significant. The interaction between the independent factor will not affect the TOC regression. Because of this, it was confirmed that there is no need for application of a more complex model than linear regression.

It can be seen (

Table 4) that the R

2 values for the two models are high, and the models are well fitted to the data. In the Fe

0/H

2O

2 process after acidification at pH 3.0, the mass ratio significance was 0.855, which higher than 5%. So, it was excluded from the model.

It can be concluded that the most important factor for the Fe0/H2O2 process is time. This can also be confirmed from the high negative correlation between the time and the TOC concentration, even though it can be seen from Equations (4) and (5) that the highest removal can be due to an increase in iron mass. This is due to the unit step difference between the time and iron mass. The time was duplicated while the iron mass amount was four time more for each step.

4.5. Possibility of Practical Application of The Process and Cost Consideration

The Fenton process and its modifications have been known for a very long time, but they have mainly been tested on the laboratory scale and sometimes in pilot studies. There are very few installations operating on an industrial scale, especially when compared to installations using conventional technologies such as coagulation or activated sludge. To our knowledge, in Poland, there are only a few Fenton process installations at the full technical scale, and they are very young, not older than 10 years. The studied processes are not conventional for wastewater treatment. Typical analyzed coasts are related to electricity and reagent consumption [

59]. It is described in scientific articles, not as a practical implementation. As is well known, costs change according to plant size, type of reagents, energy demand, etc. For each country, the legal regulations are different, as are labor or investment costs. Because of this, it is hard to predict the total treatment costs.

Another challenge that need to be solved is the transfer from the laboratory scale into the industrial one, which most likely decreases the process effectiveness. As a coagulation reactor, leachate storage tanks could be used. The tanks for sedimentation, the Fe0/H2O2 process, and final sedimentation also need to be built. Usually, landfills have enough space and the possibility for their construction.

Some costs will be generated by the reagents, but the reagents used for coagulation and pH adjustment are cheap and readily available. In the case of metallic iron, it does not have to be used in the form of chemically pure metal. Metallurgical waste or steel shots could be used to decrease costs. After the Fe0/H2O2 process, residual solid catalyst could be reused. The material can be separated from treated LL in two ways: electromagnetically or through sedimentation.

Now, AOPs are more expensive than conventional treatment. Because of their high predicted installation costs in Poland for current legal regulations regarding labor and investment costs, unfortunately, we can see no chance for this research to have practical implementation.